Release time:2024年4月25日

Author:Kama

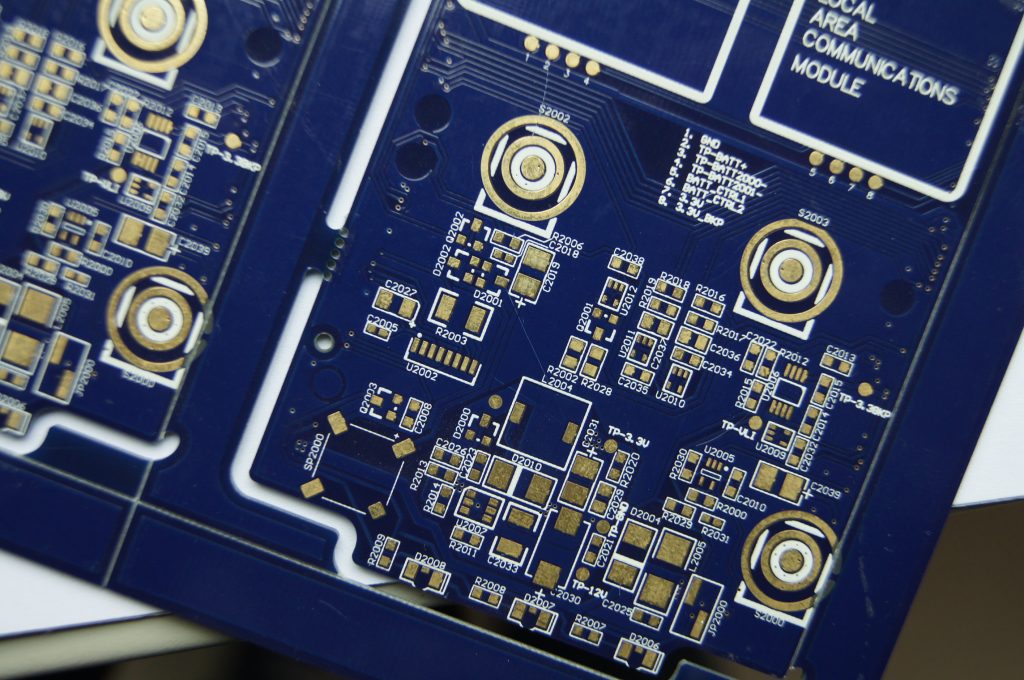

In the dynamic world of electronics, speed is often the key to success. Whether you're a hobbyist tinkering with your latest project or a large-scale manufacturer pushing out cutting-edge devices, the ability to rapidly prototype and iterate is invaluable. This is where Quick Turn PCB (Printed Circuit Board) manufacturing plays a crucial role.

Introduction to Quick Turn PCBs

Printed Circuit Boards (PCBs) are the backbone of nearly all modern electronic devices. They provide mechanical support and electrical connections for various components, enabling the functionality of devices ranging from smartphones to industrial machinery. Traditionally, the PCB manufacturing process involved lengthy lead times, often spanning several weeks or even months. However, the demand for faster turnaround times has led to the emergence of Quick Turn PCB services.

A Quick Turn PCB refers to a circuit board produced with an expedited manufacturing process. Unlike standard PCB fabrication, which may take weeks to complete, Quick Turn PCBs are designed to be produced in significantly shorter timeframes, typically ranging from 24 hours to a few days. This accelerated production timeline allows electronics designers and engineers to rapidly iterate their designs, test prototypes, and bring products to market faster.

In today's fast-paced electronics industry, time-to-market is a critical factor for success. Companies need to quickly respond to market demands, technological advancements, and competitive pressures. Quick Turn PCB manufacturing addresses this need by enabling rapid prototyping and production ramp-up, reducing the time and cost associated with traditional PCB fabrication processes.

Rapid Prototyping: Quick Turn PCB services offer rapid prototyping capabilities, allowing designers to quickly validate their designs and make necessary adjustments. This agility accelerates the product development cycle and enhances the overall innovation process.

Short Lead Times: One of the defining characteristics of Quick Turn PCBs is their short lead times. Manufacturers prioritize speed without compromising on quality, ensuring that customers receive their PCBs within days rather than weeks.

Flexible Order Quantities: Quick Turn PCB services cater to a wide range of order quantities, from small prototype runs to large-scale production batches. This flexibility enables businesses of all sizes to benefit from expedited PCB manufacturing.

High-Quality Manufacturing: Despite the accelerated timeline, Quick Turn PCBs uphold high standards of quality and reliability. Advanced manufacturing techniques, stringent quality control processes, and experienced engineers ensure that the final product meets or exceeds customer expectations.

While traditional PCB fabrication involves multiple steps and lengthy lead times, Quick Turn PCB manufacturing streamlines the process for faster turnaround. Here's an overview of the typical steps involved:

Design Submission: Customers submit their PCB designs, typically in Gerber file format, along with any specific requirements or preferences.

Design Review: Experienced engineers review the design files to ensure manufacturability and identify any potential issues or optimizations. This step is crucial for minimizing errors and maximizing efficiency throughout the manufacturing process.

Material Procurement: Once the design is approved, the manufacturer procures the necessary materials, including copper-clad laminates, solder mask, and silkscreen materials.

Board Fabrication: The PCB fabrication process begins with the production of bare circuit boards. This involves laminating copper onto substrate materials, etching away excess copper to create circuit traces, and applying solder mask and silkscreen layers.

Component Assembly: Once the bare boards are fabricated, surface-mount or through-hole components are assembled onto the boards using automated pick-and-place machines and soldering techniques.

Testing and Inspection: After assembly, each PCB undergoes rigorous testing and inspection to ensure functionality and quality. This may include electrical testing, automated optical inspection (AOI), and functional testing.

Shipping and Delivery: Upon successful testing and inspection, the finished PCBs are packaged and shipped to the customer's specified location, ready for integration into their electronic products.

Quick Turn PCBs find applications across various industries and sectors, including:

Consumer Electronics: Companies developing smartphones, tablets, wearables, and other consumer devices rely on Quick Turn PCBs to stay ahead of market trends and deliver innovative products to consumers.

IoT (Internet of Things): The rapid pace of IoT innovation demands quick prototyping and iteration. Quick Turn PCBs enable IoT developers to rapidly prototype and deploy connected devices and sensor networks.

Medical Devices: The healthcare industry benefits from Quick Turn PCBs for rapid prototyping of medical devices, diagnostic equipment, and wearable health monitors.

Automotive: Automotive manufacturers use Quick Turn PCBs for prototyping advanced driver-assistance systems (ADAS), infotainment systems, and vehicle control modules.

Conclusion

Quick Turn PCB manufacturing has revolutionized the electronics industry by offering expedited prototyping and production capabilities. By minimizing lead times, enhancing agility, and maintaining high quality, Quick Turn PCB services empower designers, engineers, and businesses to accelerate innovation and bring cutting-edge products to market faster than ever before. As technology continues to advance and market demands evolve, Quick Turn PCBs will remain a vital enabler of progress and growth in the electronics ecosystem.

In the fast-paced world of electronics, speed is of the essence. Whether you're a hobbyist tinkering with your latest project or a large-scale manufacturer pushing out cutting-edge devices, the ability to rapidly prototype and iterate is invaluable. This is where Quick Turn PCB (Printed Circuit Board) manufacturing plays a crucial role.

1.Top PCBA Services Suppliers and Manufacturers in the world