Release time:2024年4月26日

Author:Kama

Market Size and Growth:

The global printed circuit board (PCB) market was valued at USD 60.01 billion in 2020 and is projected to reach USD 79.27 billion by 2026, with a CAGR of 4.3% during the forecast period (2021-2026). [Source: Mordor Intelligence]

The printed circuit board assembly (PCBA) market is anticipated to grow at a similar pace due to increasing demand for consumer electronics, automotive electronics, and IoT devices. [Source: ResearchAndMarkets]

Industry Trends:

Miniaturization: The trend toward miniaturization of electronic devices is driving the demand for complex multi-layer PCBs capable of accommodating densely packed components. [Source: Grand View Research]

Automation: Adoption of automated assembly processes, including robotics and AI-driven inspection systems, is on the rise to enhance efficiency and quality in PCBA. [Source: Deloitte]

| Aspect | Printed Circuit Board (PCB) | Printed Circuit Board Assembly (PCBA) |

| Functionality | Serves as the physical platform for electronic components. | Involves assembling electronic components onto a fabricated PCB. |

| Manufacturing Process | Encompasses design layout, fabrication, and copper etching. | Involves soldering electronic components onto the fabricated PCB. |

| Complexity | Varies from simple single-layer designs to intricate multi-layer configurations. | Adds complexity by integrating various electronic components onto the PCB. |

| Role in Electronics Industry | Fundamental building blocks in the electronics industry. | Crucial in producing functional electronic devices. |

To commence our exploration, it's imperative to elucidate the essence of a Printed Circuit Board (PCB). Essentially, a PCB serves as the fundamental platform upon which electronic components are interconnected to form a functional circuit. These boards are typically composed of insulating material, commonly fiberglass, with thin layers of conductive copper laminated onto their surface. The copper traces etched onto the PCB provide pathways for electrical currents to flow between various components, facilitating the transmission of signals and power throughout the circuit.

PCBs come in various forms, ranging from single-layer pcb, which are simpler and comprise a single layer of conductive material, to double-layer and multi-layer pcb, which exhibit increased complexity and can accommodate more intricate circuit designs. The design of a PCB is meticulously crafted to accommodate the specific requirements of the electronic device it is intended to support, encompassing considerations such as component placement, routing of traces, and adherence to design guidelines for optimal functionality and manufacturability.

Moving beyond the bare PCB, we encounter the realm of Printed Circuit Board Assembly (PCBA). PCBA represents the culmination of the manufacturing process, wherein electronic components are affixed onto the PCB to actualize the envisioned circuit. This process transforms the inert PCB into a fully functional electronic device capable of performing its intended tasks.

The PCBA process encompasses a series of intricate steps, beginning with the procurement of electronic components, including resistors, capacitors, integrated circuits, and various other active and passive elements essential for the circuit's operation. These components are meticulously selected based on factors such as performance specifications, reliability, and compatibility with the intended application.

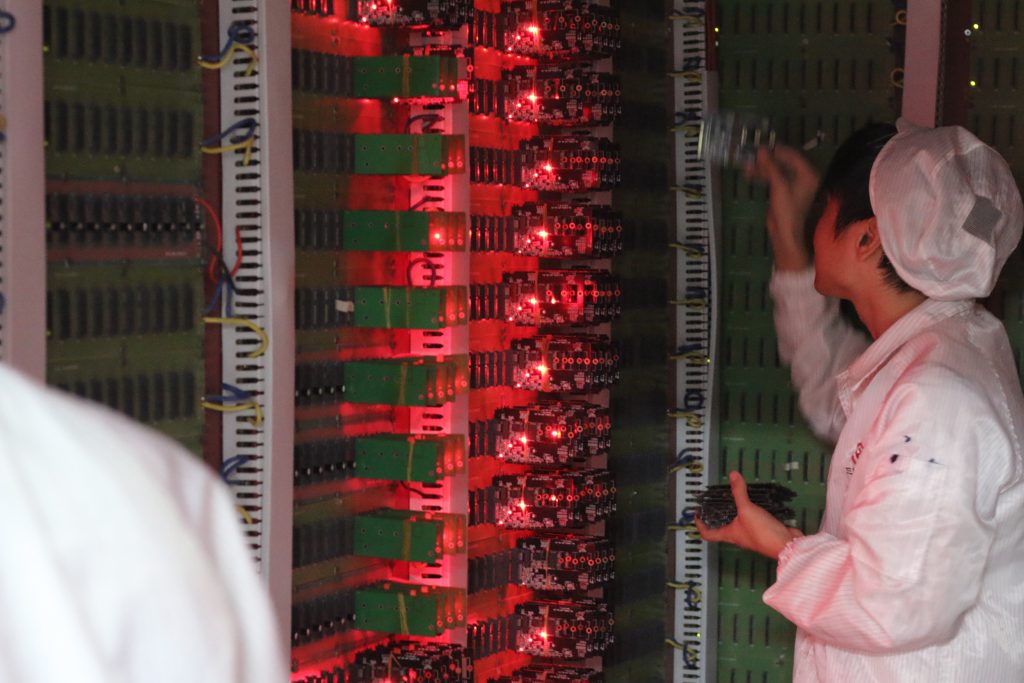

Once the components are acquired, the assembly process commences. This typically involves automated machinery or manual labor, depending on the scale and complexity of the production. Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two prevalent methodologies employed in component placement and soldering processes.

In Surface Mount Technology, miniature electronic components are mounted directly onto the surface of the PCB, utilizing solder paste and reflow soldering techniques to establish secure electrical and mechanical connections. This approach offers advantages such as enhanced component density, reduced manufacturing footprint, and improved signal integrity, making it ideal for compact and high-performance electronic devices.

Conversely, Through-Hole Technology involves inserting electronic components into pre-drilled holes on the PCB, with leads extending through the board for soldering on the opposite side. While less prevalent in modern electronics manufacturing, THT remains relevant for applications requiring robust mechanical connections or compatibility with legacy components.

Following component placement and soldering, the assembled PCB undergoes rigorous inspection and testing to ensure adherence to quality standards and functional integrity. This phase encompasses various techniques, including visual inspection, automated optical inspection (AOI), and functional testing, aimed at identifying defects, verifying electrical connectivity, and validating the circuit's functionality.

Upon successful completion of testing, the assembled PCB transitions to the final stages of production, which may entail additional processes such as conformal coating application, labeling, and packaging for shipment to end-users or integration into larger assemblies.

Having elucidated the intricacies of PCBs and PCBA, it becomes evident that while they are interrelated components within the electronics manufacturing ecosystem, they serve distinct functions and exhibit unique characteristics.

PCB: At its core, a PCB serves as the foundational substrate upon which electronic components are interconnected to form a circuit. It provides mechanical support, electrical connectivity, and facilitates the transmission of signals and power between components. The design of a PCB is pivotal in determining the functionality, performance, and manufacturability of the electronic device it underpins.

PCBA: Conversely, PCBA represents the culmination of the manufacturing process, wherein electronic components are assembled onto the PCB to create a functional electronic circuit. This process involves component procurement, placement, soldering, inspection, and testing, culminating in the transformation of the inert PCB into a fully operational electronic device ready for deployment.

In essence, PCBs lay the groundwork for electronic circuits, while PCBA brings them to life, imbuing them with functionality and purpose. Understanding the disparity between these two entities is essential for stakeholders within the electronics industry, encompassing designers, manufacturers, engineers, and end-users alike, as it facilitates informed decision-making, fosters collaboration, and ensures the seamless realization of innovative electronic devices.

Asia Pacific dominates the PCB and PCBA market, accounting for a significant share of global production, driven by the presence of major electronics manufacturing hubs in countries like China, Taiwan, South Korea, and Japan. Huaxing is one of the top suppliers about pcba services in China.[Source: Statista]

North America and Europe also play crucial roles in PCB and PCBA manufacturing, with a focus on high-end applications in aerospace, defense, and telecommunications industries. [Source: MarketWatch]

Supply Chain Disruptions: The electronics industry faces challenges related to supply chain disruptions, including shortages of critical components and fluctuations in raw material prices. [Source: McKinsey & Company]

Sustainability Initiatives: There is a growing emphasis on sustainability in electronics manufacturing, driving initiatives to reduce waste, energy consumption, and environmental impact throughout the PCB and PCBA lifecycle. [Source: Electronics Weekly]

In conclusion, the differentiation between PCBs and PCBA lies at the heart of electronics manufacturing, delineating the stages involved in transforming conceptual designs into tangible electronic devices. While PCBs provide the structural and electrical framework for circuits, PCBA breathes life into them, transforming inert boards into functional devices through meticulous assembly processes. By comprehending the nuances of PCBs and PCBA, stakeholders can navigate the complexities of electronics manufacturing, driving innovation, and advancing technological frontiers in the pursuit of excellence.

Recommended reading

1.Factors Influencing Prices for PCB Manufacturing and Assembly