Release time:2024年4月26日

Author:Kama

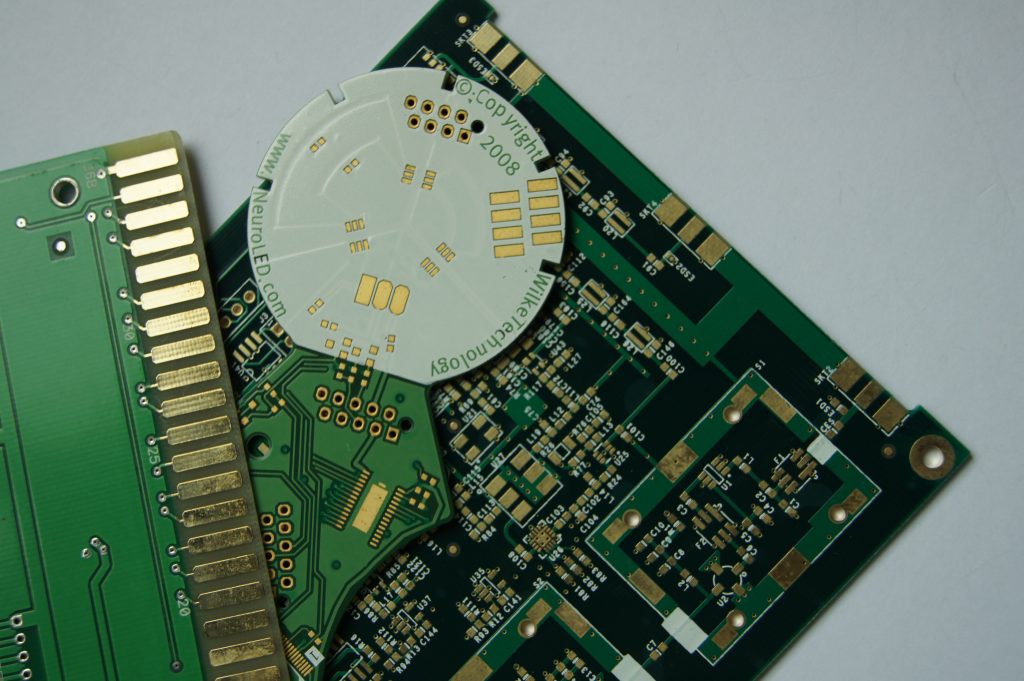

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing the foundation for seamless connectivity and operation of electronic components. Understanding what comprises PCBs is crucial for grasping their functionality and importance across various industries, from consumer electronics to aerospace. In this article, we will delve into the composition of PCBs, explore the materials that make up key components of electronic devices, and present their significance in modern technology with authoritative data and arguments.

Printed Circuit Boards (PCBs) are vital components in modern electronics, providing a sturdy platform for electrical circuits. Constructed from insulating materials like glass fiber reinforced epoxy resin, FR-4 is the most common substrate material, defined by IPC standards. PCB construction begins with meticulous layout design, translating schematics into blueprints using specialized software. Copper foil is then applied to the substrate, forming conductive pathways through etching, creating the circuitry's foundation. Additional layers of insulating material may be laminated for durability and complexity. Rigorous testing ensures adherence to performance standards before integration into electronic devices. This process, blending precision engineering and craftsmanship, underscores PCBs' ubiquitous role in contemporary technology.

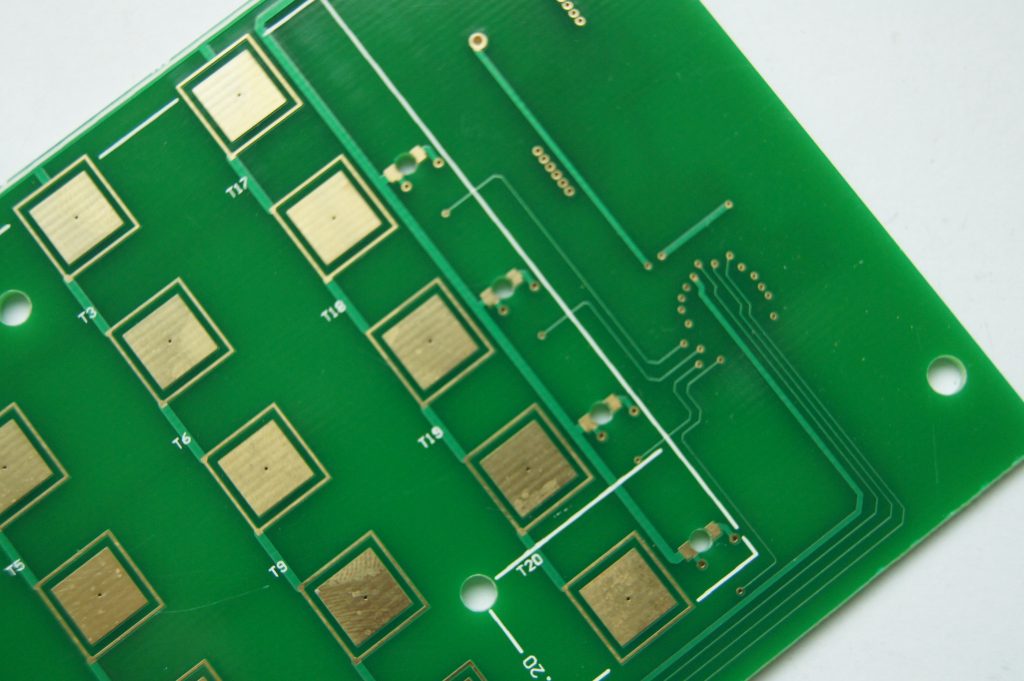

Copper Foil:

Copper foil is integral to printed circuit boards (PCBs), crucial in facilitating electrical connectivity within electronic devices. The global copper foil market reached $12 billion in 2019, expected to rise to $16 billion by 2025, boasting a Compound Annual Growth Rate (CAGR) of 4%. This growth is propelled by copper foil's exceptional conductivity and ease of processing, making it a preferred material in PCB manufacturing.

Copper foil's importance lies in its ability to transmit electrical signals effectively, enabling seamless operation across various electronic applications. Its role in PCBs is foundational, embodying the nexus of innovation and functionality in modern electronics.

In essence, copper foil's trajectory mirrors the relentless pace of technological advancement, symbolizing the evolution of electronic devices. Its journey underscores the indispensable role it plays in powering the interconnected world of electronics, driving innovation forward. As technology continues to advance, copper foil remains steadfast, poised at the forefront of progress, ensuring the reliability and efficiency of electronic devices for years to come.

Solder Mask:

The solder mask is a vital layer on PCBs, protecting copper traces from oxidation and environmental damage. Industry forecasts predict the global market to grow steadily at around 3.5% annually, reaching approximately $3 billion by 2025. This growth is fueled by increasing demand for electronic devices across industries, coupled with advancements in technology and the rise of IoT devices. As manufacturers prioritize reliability, the adoption of advanced solder mask technologies is expected to increase, further driving market expansion. Overall, the solder mask plays a crucial role in maintaining the functionality and longevity of electronic devices in today's interconnected world.

Silkscreen:

The silkscreen layer on PCBs serves as a crucial component, offering essential labels and markings that aid in identification and operation during various stages, including assembly, testing, and maintenance. These markings facilitate efficient handling of PCBs, enabling technicians to identify components, reference polarity, and ensure accurate placement during assembly processes. Additionally, silkscreen labels often include important information such as part numbers, component values, and reference designators, which are indispensable for troubleshooting and repair activities

Industry projections indicate a steady growth trajectory for the global PCB silkscreen market in the coming years. With advancements in manufacturing processes and an increasing demand for electronic devices across various sectors, the market is anticipated to surpass $1 billion by 2025. This growth reflects the indispensable role of silkscreen layers in enhancing the efficiency and accuracy of PCB assembly and maintenance operations, thereby contributing to the overall reliability and performance of electronic devices.

Other Components:

Besides core materials, PCBs incorporate various components like vias, Surface Mount Devices (SMDs), and through-hole components. The global SMD market is projected to grow steadily, reaching approximately $58 billion by 2025. This growth is driven by factors such as increased demand for compact electronics, advancements in miniaturization, and the rise of IoT devices. SMDs offer benefits like smaller sizes, higher density, and compatibility with automated assembly, making them integral to modern electronic designs. Their widespread adoption across industries underscores their significance in enabling the development of innovative and high-performance electronic products.

Here's a table presenting key market data:

| ponent | 2019 Market Size (USD Billion) | 2025 Projected Market Size (USD Billion) | CAGR (%) |

| Copper Foil | 12 | 16 | 4 |

| Solder Mask | - | 3 | 3.5 |

| Silkscreen | - | 1 | - |

| Surface Mount Devices (SMDs) | - | 58 | - |

By delving into the composition of PCBs and combining specific data and arguments, we can better understand the roles and importance of these key components in modern technology. As the foundation of electronic devices, the continual innovation of PCBs materials and technology will further drive the development of the electronics industry, addressing increasingly complex market demands and technological challenges. With the continued growth of the global electronics industry, PCBs, as a vital component thereof, will continue to play a crucial role in advancing technology and societal development.

1.The best solder for electronics

3.Factors Influencing Prices for PCB Manufacturing and Assembly